GN 187.5 Stainless Steel Locking Plates

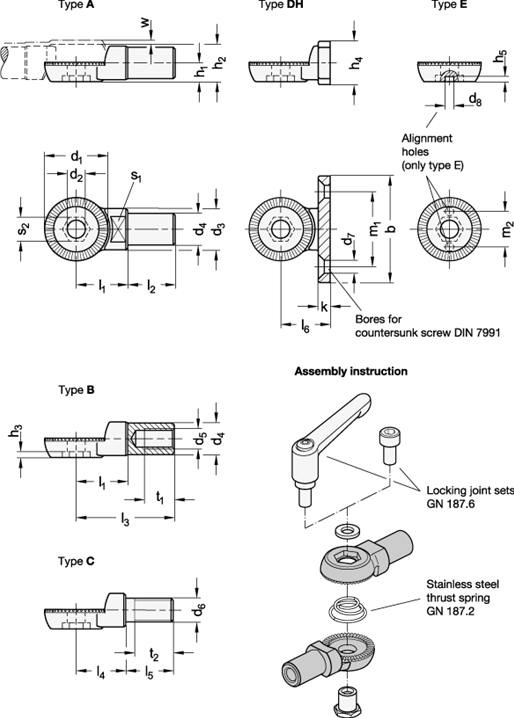

Type

| A | Stud, unthreaded (for welding on) |

| B | Stud, with internal thread |

| C | Stud, with external thread |

| DH | Fastening flange, horizontal |

| E | Plate (for welding on) |

| d1 | z Number of teeth | b | d2 | d3 | d4 | d5 | d6 | d7 | d8 | h1 Middle of the teeth | h2 | h3 | h4 | h5 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 27 | 48 | 60 | 46 | 9 | 18 | 13 | M 8 | M 10 | 5,3 | 2,5 | 8 | 16 | 3 | 20 | 1,5 |

| 32 | 48 | 60 | 54 | 9 | 21 | 16 | M 10 | M 12 | 6,5 | 3 | 9,5 | 19 | 3 | 22 | 2 |

| 40 | 48 | 60 | 70 | 11 | 27 | 20 | M 12 | M 16 | 8,5 | 4 | 12 | 24 | 4 | 30 | 2,5 |

| d1 | k | l1 | l2 | l3 | l4 | l5 | l6 | m1 | m2 | s1 | s2 | t1 | t2 | w min. Stroke |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 27 | 5 | 21 | 20 | 40,5 | 21 | 20 | 21 | 32 | 17 | 14 | 12 | 12 | 17 | 0,8 |

| 32 | 6 | 26 | 24 | 49,5 | 25 | 24 | 25 | 38 | 20 | 17 | 12 | 15 | 20 | 0,8 |

| 40 | 7 | 31,5 | 32 | 63 | 31 | 32 | 30,5 | 48 | 24 | 22 | 14 | 18 | 26 | 1 |

Specification

Matte shot-blasted

RoHS

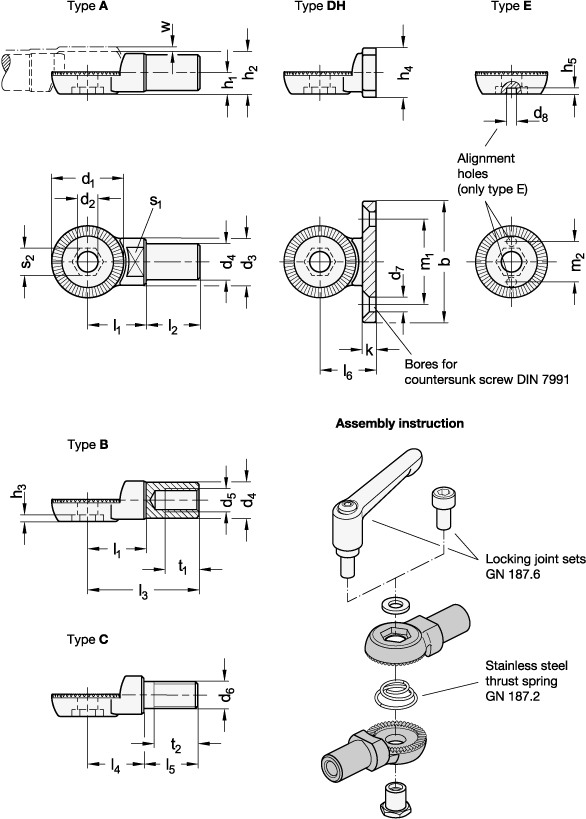

Accessory

Locking Joint Sets GN 187.6Serrated Locking Plates (Steel / Stainless Steel) GN 187.4

Stainless Steel Thrust Springs GN 187.2

Information

Stainless steel locking plates GN 187.5 can be installed in combination with locking joint sets GN 187.6 to create locking joints. This allows gear lever handles and retaining tubes or trays and mounts to be adjusted relative to each other at defined angles with a form-locking connection. The angle orientation of the teeth is adapted to the connecting elements, permitting an axis-parallel or right-angled arrangement.

Held together and centered by locking joint sets, the various types can be combined together arbitrarily with identical the nominal sizes d1. Stainless steel thrust springs GN 187.2 can be placed between the locking heads during mounting, allowing a clean separation upon removal. Additional design possibilities arise from the compatibility of the locking heads with the locking plates GN 187.4.

When welding on, type E be easily positioned on the opposing part and fastened by means of the mounting holes d8 (which are aligned with the teeth) using dowel pins or positioning pins.

see also...

| How to order |

| ||||||||

GN 187.5-32-48-DH-NI |

This could also be interesting...

-

-

-

-