Knob Side Hygienic Design (Front Hygiene), Certified acc. DGUV Test

GN 8170 Stainless Steel Indexing Plungers

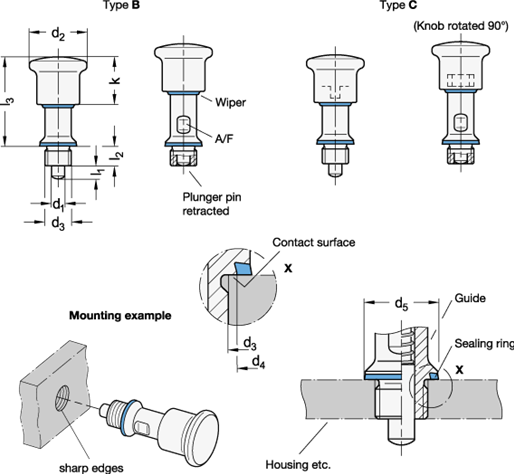

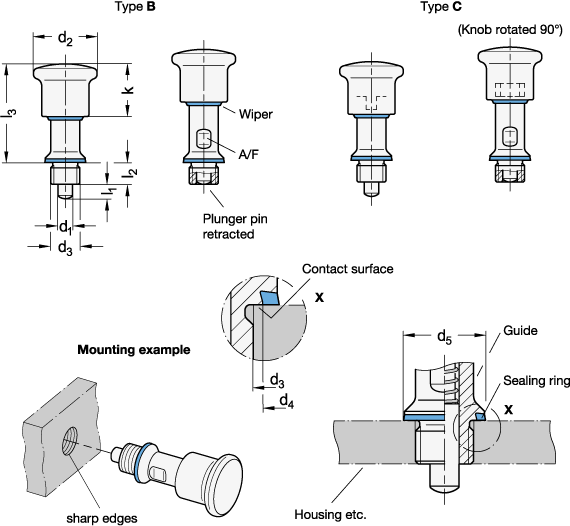

Type

| B | Without rest position |

| C | With rest position |

Identification

| FH | Knob side Hygienic Design (front hygiene) |

| d1 Plunger f8 Bore H8 | d2 | d3 | d4 | d5 | l1 | l2 | l3 | A/F1 | Spring load in N ≈ initial | end | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 35 | M 12 x 1,5 | 18 | 22,8 | 6 | 12 | 49,8 | 29 | 14 | 20 | 36 |

| 8 | 35 | M 16 x 1,5 | 18 | 22,8 | 8 | 12 | 54,3 | 29 | 14 | 22 | 32 |

Specification

Plunger pin case-hardened

Pressure spring

Stainless steel AISI 316Ti

Seals, blue, FDA compliant

Temperature resistant -25 °C to +110 °C

- Sealing ring

H-NBRH

Hardness 85 ±5 Shore A - Wiper

TPU

Hardness 95 ±5 Shore A

All moving parts lubricated with FDA compliant grease

DGUV Test Certificate

Operating instruction GN 8170-FH

Brochure on Hygienic Design

Load Rating Information

ISO Fundamental Tolerances

Elastomer Characteristics

Stainless Steel Characteristics

RoHS

Information

Stainless steel indexing plungers GN 8170 are certified according to DGUV Test guidelines and meet hygiene requirements on the knob side (front hygiene).

Wipers between the knob and the guide as well as the sealing ring between the guide and the housing keep the locking mechanism on the knob side leak-tight. At the same time, the high surface quality (Ra < 0,8 µm) and dead-space-free mounting prevent dirt from adhering and facilitate cleaning.

Indexing plungers with a rest position (Type C) are used for such applications where the plunger has to stay in its retracted position. In that case, the knob is retracted and afterwards turned by 90°. A notch keeps the plunger in this position.

Mounting holes and through-holes in the housing must be at a right angle, free of burrs and without a chamfer. This ensures that the sealing rings will function properly.

| How to order |

| ||||||||

GN 8170-8-C-FH-H |

This could also be interesting...

-

-

-

-