for Locking Plates GN 187.5

GN 187.6 Locking Joint Sets

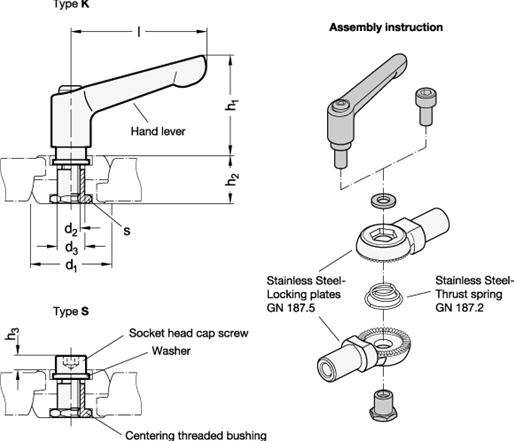

Type

| E | with clamping lever with eccentrical cam |

| K | With hand lever |

| S | with socket cap screw DIN 912 |

| d1 Locking plate GN 187.5 | d2 | d4 | h1 | h2 | h3 Stroke | h4 | h5 | l1 | l2 | s | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 27 | 9 | M 5 | M 6 | 16 | 15 | 0,9 | 33 | 4,6 | 44 | 45 | 12 |

| 32 | 9 | M 5 | M 6 | 19 | 19,3 | 1,1 | 33 | 4,6 | 63 | 45 | 12 |

| 40 | 11 | M 6 | M 8 | 24 | 25,5 | 1,3 | 42,5 | 5,6 | 82 | 63 | 14 |

Filter combination produces no result.

Specification

Type E

Type K

Hand lever

Zinc die casting

Powder coated

Black, RAL 9005, textured finish

Type S

Socket cap screw DIN 912

Stainless steel A2

Countersunk screw DIN 7991 / washer

Stainless steel A2

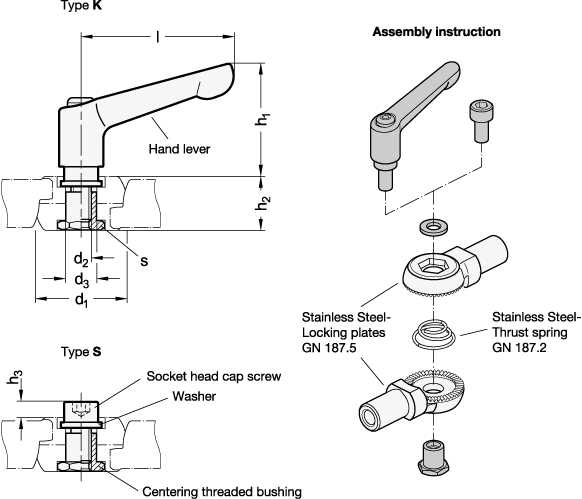

Other parts

Stainless steel AISI 303

RoHS

- Eccentric lever

Stainless steel AISI CF-8 - Contact surface

Stainless steel AISI 431

Type K

Hand lever

Zinc die casting

Powder coated

Black, RAL 9005, textured finish

Type S

Socket cap screw DIN 912

Stainless steel A2

Countersunk screw DIN 7991 / washer

Stainless steel A2

Other parts

Stainless steel AISI 303

RoHS

Information

Locking joint sets GN 187.6 can be used to combine stainless steel locking heads GN 187.5 to form locking joints. Thanks to the hexagonal shoulder, which creates a form-locking connection that prevents the part from also turning, the centering bushing allows fast and easy mounting. In the unlocked state, the bushing or draw nut forms the axis that positions the locking heads center to center.

The use of stainless steel thrust springs GN 187.2 allows the locking heads to be cleanly separated from each other.

The types E and K are used in applications requiring frequent and tool-free adjustment of the locking joints.

| How to order |

| ||||

GN 187.6-27-S |

This could also be interesting...

RoHS compliant:

-

-

-

-

Weight:

-

-

-

-

PDF not available