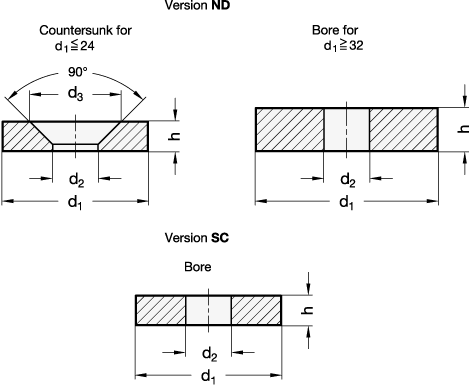

Disk-Shaped, with Bore or Countersunk

GN 55.1 Raw Magnets

d1 | SC d2 ±0,1 | h±0,1 | ND d2 ±0,1 | h±0,1 | d3+0,5 | Nominal adhesive forces in N SC Sm Co | ND NdFeB | Packaging units |

|---|---|---|---|---|---|---|---|---|

| 12 ±0,1 | - | - | 3,5 | 3 | 6,6 | - | 18 | 20 |

| 15 ±0,1 | 8 | 3,5 | 4,5 | 3,5 | 9,3 | 23 | 29 | 20 |

| 18 ±0,1 | 8 | 4 | 4,5 | 4 | 9,3 | 31 | 41 | 10 |

| 24 ±0,1 | 11 | 4 | 5,5 | 4 | 11,5 | 51 | 66 | 10 |

| 32 ±0,15 | 10 | 4 | 10,5 | 2 | - | 67 | 42 | 5 |

| 38 ±0,1 | - | - | 12 | 4 | - | - | 110 | 1 |

| 48 ±0,2 | - | - | 15 | 5 | - | - | 165 | 1 |

| 56 ±0,2 | - | - | 15 | 6 | - | - | 230 | 1 |

Specification

- SmCoSC

Samarium, cobalt

Plain

Temperature resistant up to 200 °C

- NdFeBND

Neodymium, iron, boron

Nickel-plated

Temperature resistant up to 80 °C

RoHS

On request

Information

Raw magnets GN 55.1 are unshielded disk-shaped (annular) magnets.

Owing to their vast range of different magnet materials and sizes, they are suitable for virtually universal use. They are mostly attached by gluing.

When used without air gap, individual raw magnets always have lower adhesive forces than a magnet system in which shielding and magnetic return enormously intensify the force acting at the adhesion surface. Depending on the air gap between magnet and mating component, individual raw magnets - unlike magnet systems - can have substantially higher adhesive forces.

In the event that no suitable retaining magnets / magnet systems are available, raw magnets may be used in combination with appropriate holding constructions to build up highly specific magnet systems.

see also...

| How to order |

| ||||||||

GN 55.1-ND-38-12-4 |

This could also be interesting...

-

-

-

-