with Inside Traversal Distance, Steel

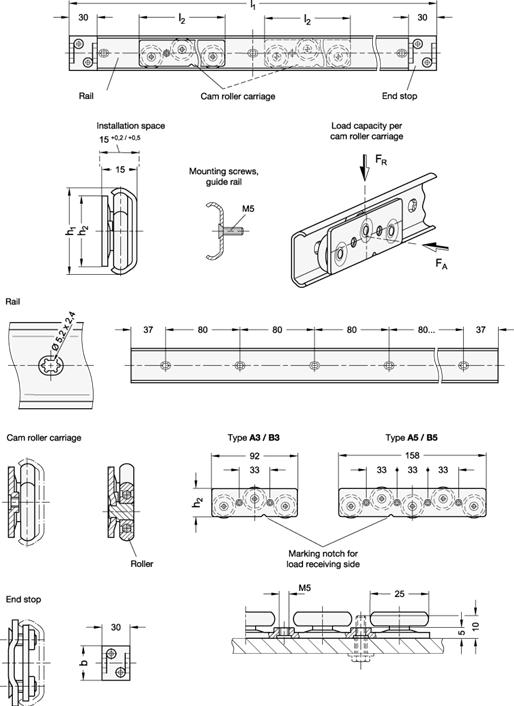

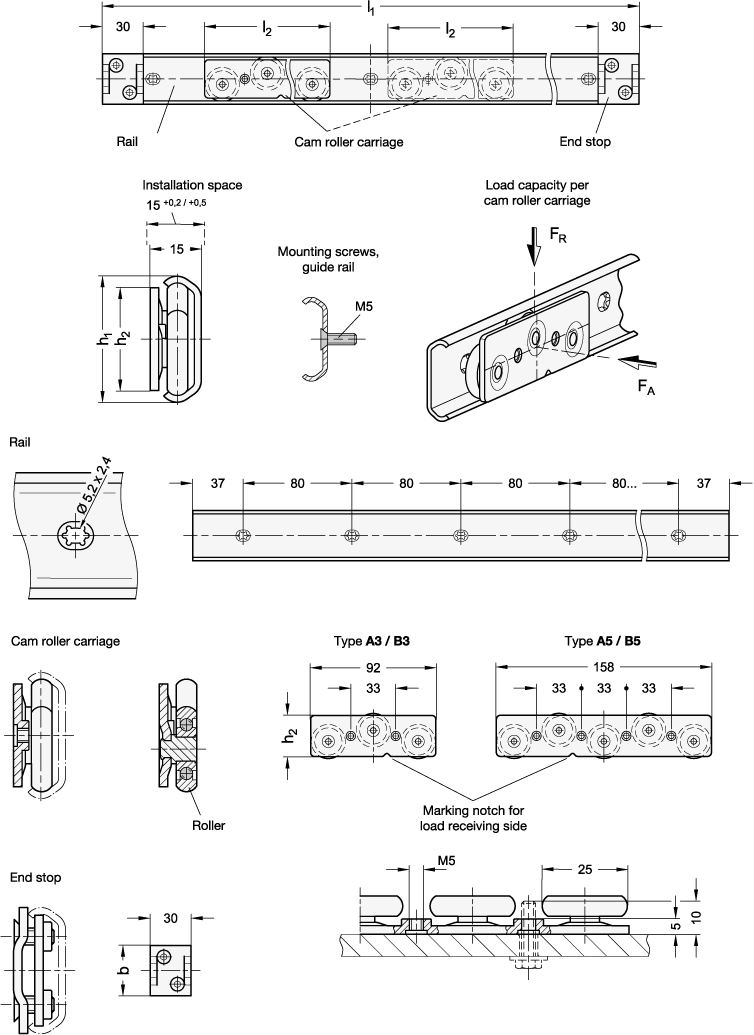

GN 1490 Linear Guide Rail Systems

Type

| A3 | with one cam roller carriage with 3 rollers |

| A5 | with one cam roller carriage with 5 rollers |

| B3 | with two cam roller carriages with 3 rollers |

| B5 | with two cam roller carriages with 5 rollers |

Identification no.

| 0 | without end stop |

| 1 | with one end stop |

| 2 | with two end stops |

| h1 | l1 ±1 | b | h2 | l2 cam roller carriage 3 rollers | 5 rollers | FR per cam roller carriage in N 3 rollers | 5 rollers | FA per cam roller carriage in N 3 rollers | 5 rollers | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 29 | 394 | 474 | 554 | 634 | 714 | 794 | 29 | 23 | 92 | 158 | 425 | 650 | 175 | 350 |

| 29 | 874 | 954 | 1034 | 1194 | 1434 | - | 29 | 23 | 92 | 158 | 425 | 650 | 175 | 350 |

| 37 | 394 | 474 | 554 | 634 | 714 | 794 | 37 | 30 | 92 | 158 | 800 | 1150 | 200 | 400 |

| 37 | 874 | 954 | 1034 | 1194 | 1434 | - | 37 | 30 | 92 | 158 | 800 | 1150 | 200 | 400 |

Specification

Zinc plated, blue passivatedZB

Cam roller carriage

- Base body

Stainless steel AISI 304 - Roller

ball-bearing, 2RS

Stainless steel AISI 440C - Roller bearing grease

FDA compliant, class H1

permanent lubrication

End stop

Stainless steel AISI 304

- Rubber stop (TPU), hardness ≈ 80 Shore A

Operating temperature -20 °C to 100 °C

Mounting holes, fastening screws / Lubrication and maintenance

Mounting and technical information GN 1490

Operation instruction GN 1490

RoHS

On request

Other hole spacing

Other mounting type / finish

Information

Linear guide rail systems GN 1490 are generally installed in pairs, with a horizontal alignment, either vertically (as shown) or perpendicularly. They are used where simple, linear movements must be executed, such as in automation or in vehicle or machine engineering.

Optimal travel properties combined with low maintenance requirements can be achieved in connection with cam roller carriages matched to the guide rails without any play. The system is ready for use immediately after insertion of the cam roller carriages.

The linear guide rail systems consist of a guide rail, one or two cam roller carriages and the selected number of end stops. The parts are delivered unassembled. The guide rail can be installed on either the left or right side of the application. During installation of the cam roller carriages, the direction in which the load is received (marking notch) must be taken into account. The lubrication and maintenance instructions must be followed.

| How to order |

| ||||||||||

GN 1490-29-1034-B3-2-ZB |

This could also be interesting...

-

-

-

-