DIN 582 Stainless Steel Lifting Eye Nuts

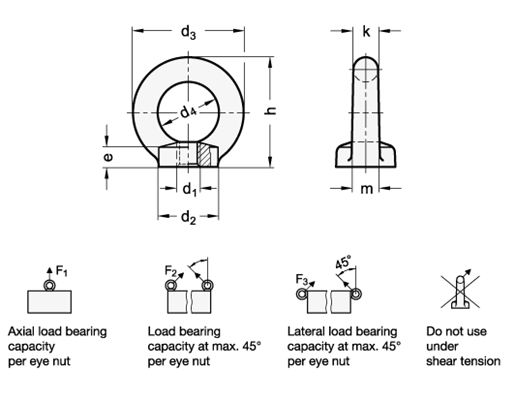

| d1 | d2 | d3 | d4 | e | h | k | m | F1 max. in N | F2 max. in N | F3 max. in N |

|---|---|---|---|---|---|---|---|---|---|---|

| M 8 | 20 | 36 | 20 | 8,5 | 36 | 8 | 10 | 1400 | 1000 | 700 |

| M 10 | 25 | 45 | 25 | 10 | 45 | 10 | 12 | 2300 | 1700 | 1150 |

| M 12 | 30 | 54 | 30 | 11 | 53 | 12 | 14 | 3400 | 2400 | 1700 |

| M 16 | 35 | 63 | 35 | 13 | 62 | 14 | 16 | 7000 | 5000 | 3500 |

| M 20 | 40 | 72 | 40 | 16 | 71 | 16 | 19 | 12000 | 8600 | 6000 |

| M 24 | 50 | 90 | 50 | 20 | 90 | 20 | 24 | 18000 | 12900 | 9000 |

Filter combination produces no result.

Specification

Stainless steelNI

RoHS

- Drop-forged

- Contact face machined

RoHS

Information

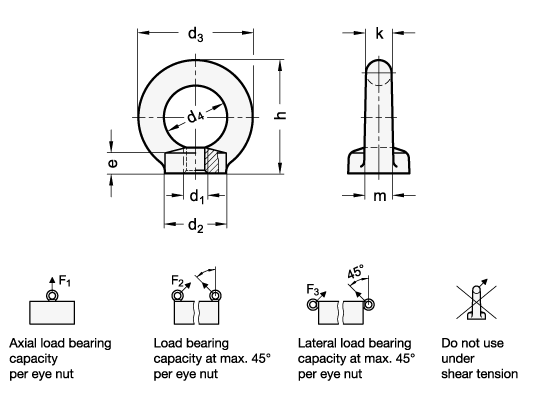

The following guidelines of the stainless steel lifting eye nuts DIN 582 have to be observed in addition to the load values given in the above table.

The eye nut must be of fully screwd in to achieve a perfect contact between the two mating faces.

Both threads must be of a equal length and the base material of equal strength to that of the nut.

Operating instructions with more details and specifications are included with every delivery (see also www.ganternorm.com/en/service).

The official DIN standard sheet specifies the additional sizes M42, M48, M56, M64, M72 x 6, M80 x 6 und M100 x 6.

| How to order |

| ||||

DIN 582-M24-NI |

This could also be interesting...

RoHS compliant:

-

-

-

-

Weight:

-

-

-

-

PDF not available