with Rotating Shaft

GN 751.1 Fork Joints

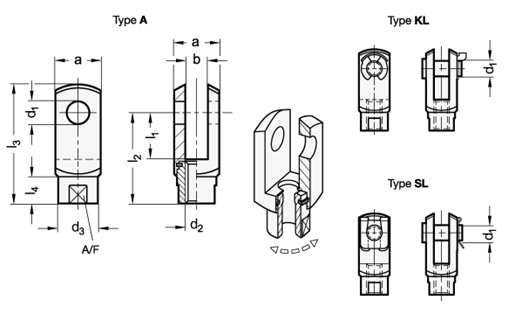

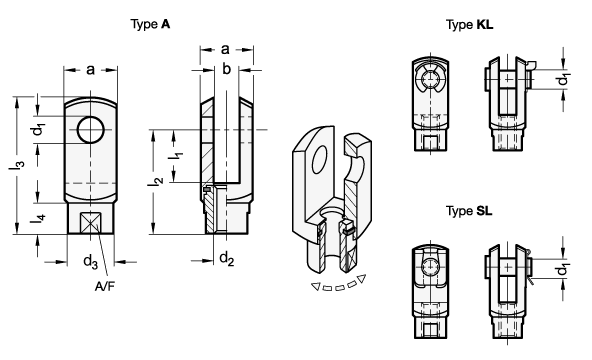

Type

| A | Without pin |

| KL | Pin with KL-shaft safety |

| SL | Pin with SL-shaft safety |

| d1 H9/h11 | l1 Short/ Long | d2 | a | b | d3 | l2 Short | Long | l3 Short | Long | l4 | A/F | Static load FA in N | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 20 | M 5 | 10 | 5 | 9 | 20 | 30 | 26 | 36 | 4 | 7 | 800 |

| 6 | 12 | 24 | M 6 | 12 | 6 | 10 | 24 | 36 | 31 | 43 | 5,5 | 9 | 2400 |

| 8 | 16 | 32 | M 8 | 16 | 8 | 14 | 32 | 48 | 42 | 58 | 8 | 12 | 3400 |

| 10 | 20 | 40 | M 10 | 20 | 10 | 18 | 40 | 60 | 52 | 72 | 11,5 | 16 | 6000 |

| 12 | 24 | 48 | M 12 | 24 | 12 | 20 | 48 | 72 | 62 | 86 | 14 | 18 | 14000 |

Filter combination produces no result.

Specification

Steel

Shaft safetys

RoHS

- Property class 5

- Zinc plated, blue passivated

Shaft safetys

- Spring steel

- Hardened and tempered

- Zinc plated, blue passivated

RoHS

Information

Fork joints GN 751.1 basically correspond to the fork head of DIN 71752 (Type A), but, unlike the DIN element, they have a rotating shaft and an additional pin with axial shaft safety (Type KL and SL) which can be mounted and dismantled without tools.

The rotating shaft allows non-dynamic radial movements to be compensated, movements which may occur e.g. when using cable winches. Also, there is no need for the otherwise necessary alignment of joint heads during assembly.

| How to order |

| ||||||||

GN 751.1-6-24-M6-KL |

RoHS compliant:

-

-

-

-

Weight:

-

-

-

-

PDF not available