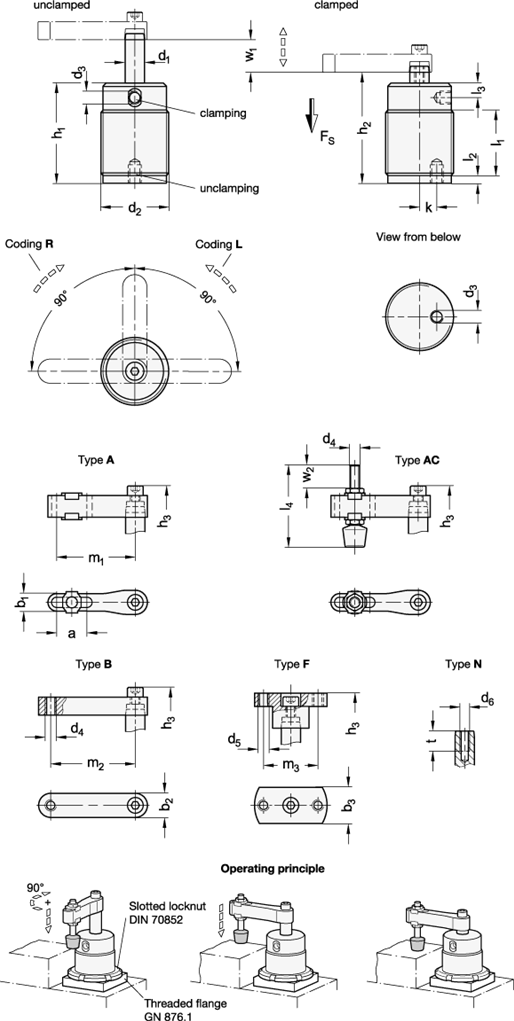

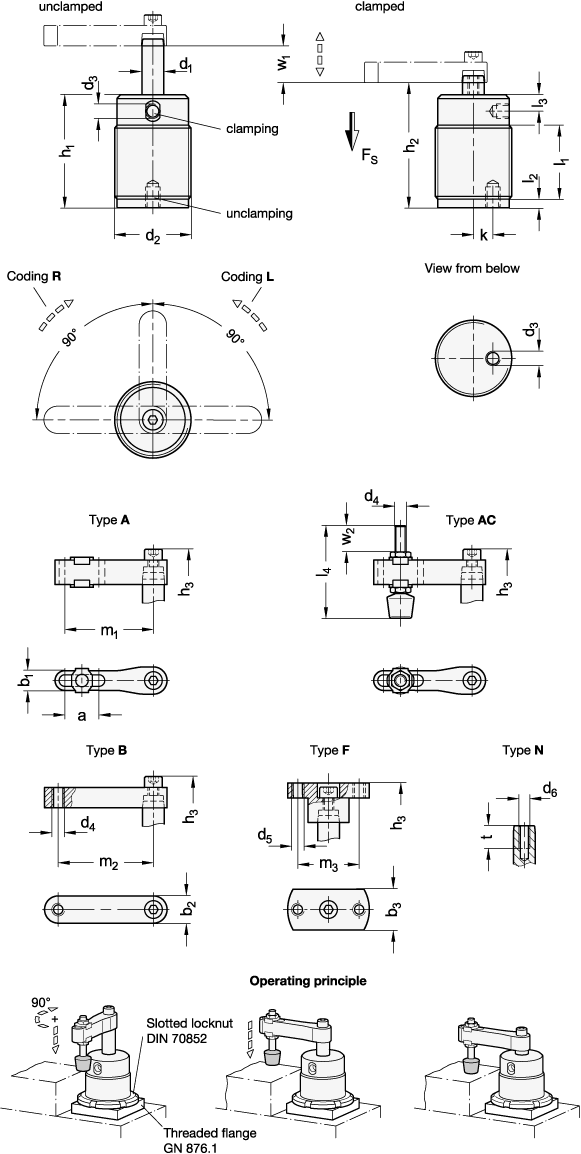

Pneumatic, with Screw-In Thread

GN 876 Swing Clamps

Type

| A | Clamping arm with slotted hole and two flanged washers |

| AC | Clamping arm with slotted hole, with two flanged washers and GN 708.1 spindle assembly |

| B | Clamping arm with threaded hole |

| F | Adapter flange |

| N | without clamping arm |

Coding

| L | Swiveling left |

| R | Swiveling right |

| Size Piston-Ø | d1 | FS in N Clamping capacity at 6 bar | a | b1 | b2 | b3 | d2 | d3 Supply port | d4 | d5 | d6 | h1 | h2 clamped | h3 ≈ unclamped Type A, AC | Type B | Type F |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 14 | 170 | 20 | 11,3 | 18 | 25 | M 40 x 1,5 | M 5 | M 6 | M 6 | M 8 | 70 | 74 | 128 | 122 | 127 |

| 32 | 16 | 270 | 25 | 14,5 | 20 | 30 | M 50 x 1,5 | G 1/8 | M 8 | M 8 | M 8 | 79 | 83 | 141 | 135 | 142 |

| 40 | 16 | 450 | 25 | 14,5 | 20 | 30 | M 55 x 1,5 | G 1/8 | M 8 | M 8 | M 8 | 83 | 87 | 144 | 141 | 145 |

| 50 | 20 | 700 | 30 | 17,5 | 25 | 32 | M 65 x 1,5 | G 1/8 | M 10 | M 8 | M 10 | 87 | 92 | 156 | 156 | 151 |

| 63 | 20 | 1100 | 30 | 17,5 | 25 | 32 | M 80 x 1,5 | G 1/8 | M 10 | M 8 | M 10 | 92 | 97 | 162 | 162 | 157 |

Filter combination produces no result.

| Size Piston-Ø | d1 | k | l1 | l2 | l3 | l4 | m1 | m2 | m3 | t ≈ | w1 Clamping stroke | Stroke | w2 | max. tightening torque of the clamping arm in Nm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 14 | 8,9 | 43 | 3 | 16 | 55 | 50 | 50 | 38 | 14 | 14 | 28 | 18 | 9 |

| 32 | 16 | 12,7 | 54 | 3 | 12 | 68 | 65 | 60 | 45 | 16 | 14 | 30 | 21 | 18 |

| 40 | 16 | 14,3 | 58 | 3 | 12 | 68 | 65 | 70 | 45 | 16 | 14 | 29 | 21 | 18 |

| 50 | 20 | 17,8 | 61 | 3 | 12 | 77 | 85 | 80 | 48 | 16 | 14 | 29 | 19 | 35 |

| 63 | 20 | 20,3 | 64 | 3 | 13 | 77 | 85 | 90 | 48 | 16 | 15 | 30 | 19 | 35 |

Filter combination produces no result.

Specification

Aluminum

Hard anodized

Wear-resistant surface

Double-action air cylinder

Max. pressure 6 bar

Socket cap screw DIN 912

Steel, zinc plated, blue passivated

Washer ISO 7092

Steel, zinc plated, blue passivated

Spindle assembly GN 708.1, type A

RoHS

Hard anodized

Wear-resistant surface

Double-action air cylinder

Max. pressure 6 bar

Socket cap screw DIN 912

Steel, zinc plated, blue passivated

Washer ISO 7092

Steel, zinc plated, blue passivated

Spindle assembly GN 708.1, type A

- Steel, zinc plated

- Rubber tip 85 Shore A

RoHS

Accessory

Clamping Arms GN 875.2Clamping Arms GN 875.3

Adapter Flanges GN 875.4

Threaded Flanges GN 876.1

Toggle Clamp Spindle assemblies GN 708.1

Slotted Locknuts DIN 70852

Information

Swing clamps GN 876 are used when the clamping point for inserting and removing the workpiece must be freely accessible on top.

The design allows especially space-saving mounting. The height of the swing clamp can be adjusted via the screw-in thread.

During the clamping action, the arm is first swiveled by 90° and lowered, followed by the linear tensioning motion. The workpiece clamping must take place within the clamping stroke.

The angle orientation of the clamping arm can be set arbitrarily during mounting on the swing clamp. When tightening the screw, the piston rod must not experience any torque. The clamping arm must therefore be held to prevent twisting.

see also...

| How to order |

| ||||||||

GN 876-32-16-L-A |

This could also be interesting...

RoHS compliant:

-

-

-

-

Weight:

-

-

-

-

PDF not available