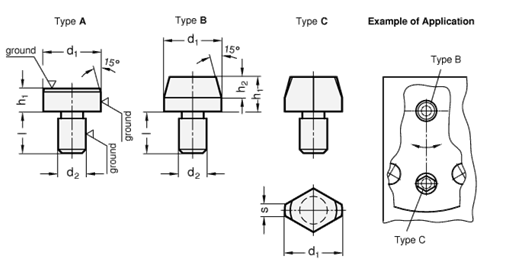

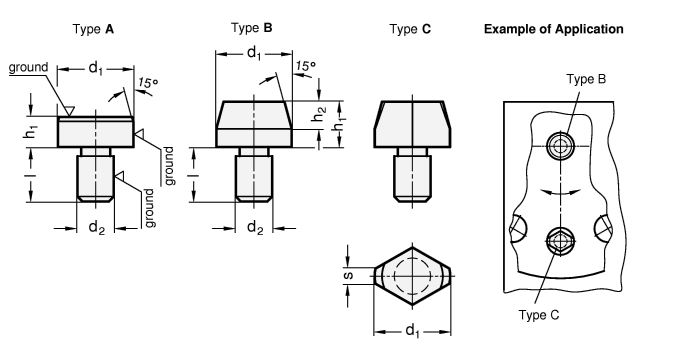

DIN 6321 Workholding Bolts / Headed Dowels

Type

| A | Headed dowel, low Type |

| B | Workholding bolt, high, cylindrical |

| C | Workholding bolt, high, flattened |

| d1 g6 Type A | Type B / C | h1 h9 Type A | h1 ±0,1 Type B / C | d2 n6 | h2 Type B / C | Length l | s ≈ Type C | |

|---|---|---|---|---|---|---|---|---|

| 6 | 6 | 5 | 7 | 12 | 4 | 4 | 6 | 1 |

| - | 8 | - | 10 | 16 | 6 | 6 | 9 | 1,6 |

| 10 | 10 | 6 | 10 | 18 | 6 | 6 | 9 | 2,5 |

| - | 12 | - | 10 | 18 | 6 | 6 | 9 | 2,5 |

| 16 | 16 | 8 | 13 | 22 | 8 | 8 | 12 | 3,5 |

| - | 20 | - | 15 | 25 | 12 | 9 | 18 | 5 |

| 25 | 25 | 10 | 15 | 25 | 12 | 9 | 18 | 5 |

Filter combination produces no result.

Specification

Steel

Type A:

With centre hole on the bottom

Type B / Type C:

With centre hole on both sides

RoHS

- Hardened

- Blackened

Type A:

With centre hole on the bottom

Type B / Type C:

With centre hole on both sides

RoHS

Information

Workholding bolts DIN 6321 are inserted into bores for positioning, assisted by the flattened design (type C) to compensate tolerances in the spacing of two bores. Another application of this design is to fix parts to be positioned in one direction only.

Types A and B can also be used as bearing surfaces, stops or as foot.

| How to order |

| ||||||

DIN 6321-10-6-A |

This could also be interesting...

RoHS compliant:

-

-

-

-

Weight:

-

-

-

-

PDF not available