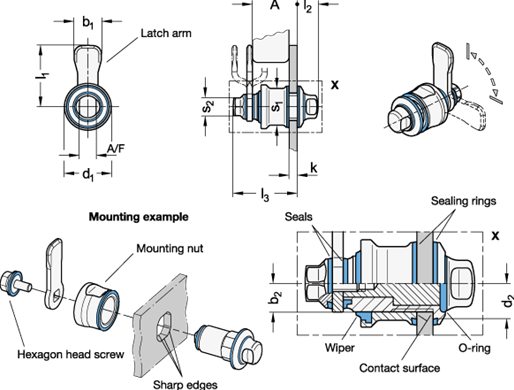

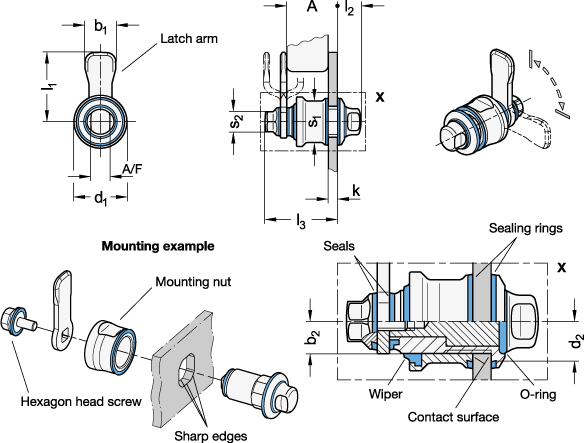

Operating and Latch Arm Side in Hygienic Design (Full Hygiene)

GN 1150 Stainless Steel Latches

Type

| SW | With two spanner flats |

Coding

| VH | Operating and latch arm side in Hygienic Design (full hygiene) |

| d1 | Latch arm distance A | b1 | b2 | d2 | k Min. | Max. | l1 +1/-1 | l2 | l3 ≈ | s1 | s2 | A/F | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 22 | 33 | 44 | 20 | 10 | 13 | 1,5 | 6 | 45 | 15,3 | 47 | 27 | 13 | 13 |

Specification

Stainless steel AISI 316L

Latch arm

Stainless steel AISI 316

Seals

Blue, FDA-compliant

Temperature resistant -40 °C to +110 °C

- Sealing rings / O-ring

EPDME

Hardness 85 ±5 Shore A (Sealing rings)

Hardness 70 ±5 Shore A (O-ring) - Other seals / Wiper

TPU, hardness 95 ±5 Shore A

Other parts

Stainless steel AISI 316L

All moving parts lubricated with FDA compliant special grease

Protection class IP 66

Technical and Assembly Instructions

Brochure on Hygienic Design

IP Protection Classes

Elastomer Characteristics

Stainless Steel Characteristics

RoHS

Information

Stainless steel latches GN 1150 are designed for use in hygienic areas and meet strict hygiene requirements (full hygiene) on the operating and latch arm side due to the special mounting nuts as well as the optimized latch arm and hexagon head screw. The locking mechanism is protected by multiple seals. At the same time, the high surface quality (Ra < 0.8 µm) and dead-space-free mounting prevent dirt from adhering and facilitate cleaning.

The latches create a secure closure by rotating a maximum of 90°, which positions the latch arm in the locked position behind the frame. Slanted surfaces on the latch arm ensure smooth positioning. Latch arms are available with different bend angles to cover a latch arm distance A from 22 to 44 mm.

The mounting holes in the housing must be at a right angle, free of burrs and without a chamfer. This ensures that the sealing rings will function properly.

| How to order |

| ||||||||||

GN 1150-30-SW-22-VH-E |

This could also be interesting...

-

-

-

-