with Threaded Stud, Contact Plate Steel

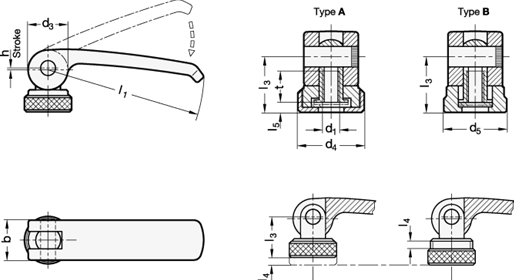

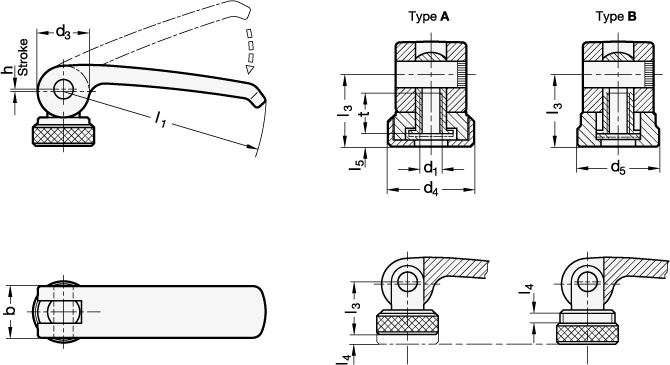

GN 927.2 Clamping Levers with Eccentrical Cam

Type

| A | Steel contact plate with setting nut |

| B | Steel contact plate without setting nut |

| l1 | d2 | l2 In clamping position | b | d3 | d4 | d5 | h Stroke at 90° lever movement | l3 In clamping position | l4 Adjustable range | l5 In clamping position | t Usable thread length | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 44 | M 4 | 12 | 16 | 20 | 25 | 30 | - | - | 12 | 12 | 15 | 14 | 0,5 | 13,2 | 2 | 2,2 | 8 |

| 44 | M 5 | 12 | 16 | 20 | 25 | 30 | 35 | 40 | 12 | 12 | 15 | 14 | 0,5 | 13,2 | 2 | 2,2 | 8 |

| 63 | M 5 | 16 | 20 | 25 | 30 | 35 | 40 | 50 | 16 | 16 | 19 | 18,5 | 0,75 | 16,3 | 2,5 | 3 | 10 |

| 63 | M 6 | 16 | 20 | 25 | 30 | 35 | 40 | 50 | 16 | 16 | 19 | 18,5 | 0,75 | 16,3 | 2,5 | 3 | 10 |

| 82 | M 6 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 20 | 20 | 25 | 22,5 | 1 | 19,5 | 3 | 3,7 | 12 |

| 82 | M 8 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 20 | 20 | 25 | 22,5 | 1 | 19,5 | 3 | 3,7 | 12 |

| 101 | M 8 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 25 | 26 | 30 | 27 | 1,5 | 25,3 | 4 | 4,8 | 15 |

| 101 | M 10 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 25 | 26 | 30 | 27 | 1,5 | 25,3 | 4 | 4,8 | 15 |

Specification

Steel (precision casting)

Zinc plated, blue passivatedZ

Axis, lag screw

Setting nut / screw (only type A)

Steel zinc plated, blue passivated

Contact plates

Steel

- Zinc flake coated

- Case-hardened

https://www.youtube.com/watch?v=WAXDnI1X7Z4

Constructional Features (Type A) / Application Examples

Clamping and Manual Forces

RoHS

On request

Other finishes

Information

Clamping levers with eccentrical cam GN 927.2 are used for rapid clamping and releasing. Contrary to a clamping operation via a thread, these levers permit torque-free clamping.

The lever has been designed to ensure that its movement cannot exceed the max. clamping force. There are no loose components since they are all assembled and mounted in their correct order.

To achieve maximum clamping forces, the clamping surface is lightly greased and should be relubricated as required.

Type A has the following advantages:

The distance between the eccentrical cam and the contact surface is adjustable by means of a fine threaded setting nut. This allows the max. clamping force to be set by a simple adjustment. In addition, this also allows the choice of the preferred lever position in relation to the clamping lever pin.

| How to order |

| ||||||||||

GN 927.2-44-M5-30-A-Z |

-

-

-

-