GN 513 Spring Elements

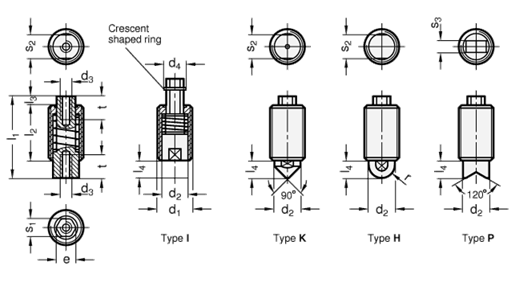

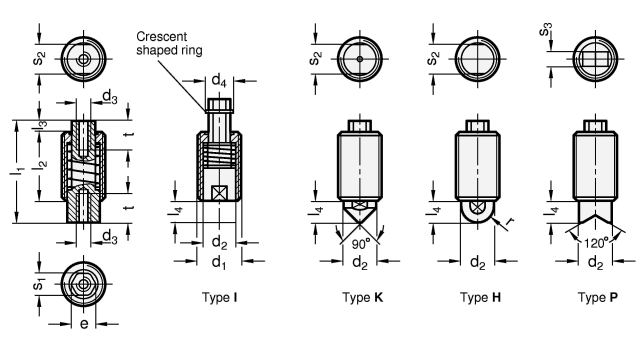

Type

| I | Female thread |

| K | Pointed nose |

| H | Semi-spherical, steel |

| P | Prism (120°) |

Identification no.

| 1 | Standard spring load |

| 2 | High spring load |

| d1 | d2 | d3 | d4 | e | l1 | l2 | l3 | l4 | r | s1 | s2 | s3 | t min. | Spring load in N ≈ Standard (Identification no. 1) initial | end | Spring load in N ≈ high (Identification no. 2) Initial | end |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M 12 x 1,5 | 9 | M 4 | 7,6 | 6,5 | 28 | 19 | 3 | 6 | 4,5 | 6 | 8 | 4 | 8 | 16 | 35 | 18 | 56 |

| M 16 x 1,5 | 12 | M 5 | 8,8 | 7,8 | 38 | 27 | 3 | 8 | 6 | 7 | 10 | 6 | 10 | 25 | 71 | 45 | 125 |

| M 20 x 1,5 | 14,5 | M 6 | 11,4 | 10 | 47 | 33 | 4 | 10 | 7,2 | 9 | 12 | 8 | 12 | 40 | 130 | 65 | 200 |

Filter combination produces no result.

Specification

Steel

Pressure spring coding

RoHS

- Threaded sleeve

Zinc plated, blue passivated - Spring bolt

Case-hardened, blackened

Pressure spring coding

- Standard spring load (Identification no. 1):

Crescent shaped ring

Phosphated (anthracite) - High spring load (Identification no. 2):

Crescent shaped ring

Zinc plated, blue passivated

RoHS

Information

Spring elements GN 513 are universal pressure elements used as detents, positioners or for clamping with spring pressure. The spring loaded nose can be used for a push-on or push-off operation. In addition the spring loaded nose cannot rotate.

At the pulling end the female thread will accept a pulling rod or an operating knob.

The version with a female thread at the pushing end (Type I) can be fitted with a special plunger nose.

The spring element can be screwed into a thread at the hexagon on the pulling end or the spanner flats at the pushing end of the plunger.

| How to order |

| ||||||

GN 513-M12x1,5-H-2 |

This could also be interesting...

RoHS compliant:

-

-

-

-

Weight:

-

-

-

-

PDF not available