for Welding

GN 722.1 Stainless Steel Spring Latches

Type

| A | Latch riveted, not removable |

| AU | Latch screwed, removable |

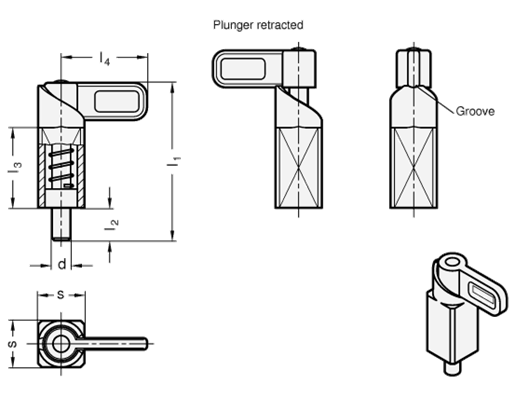

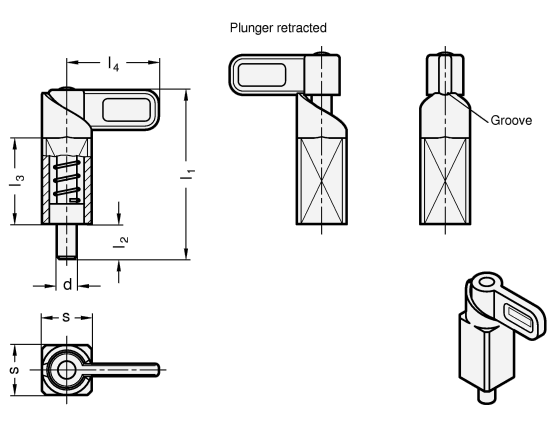

| d Pin -0,05/-0,25 Bore +0,1/+0,3 | s | l1 ≈ | l2 | l3 | l4 | A/F Type AU | Spring load in N ≈ initial | end |

|---|---|---|---|---|---|---|---|---|

| 8 | 20 | 54 | 14 | 35 | 37 | 2,5 | 15 | 50 |

| 10 | 20 | 54 | 14 | 35 | 37 | 2,5 | 15 | 50 |

| 12 | 20 | 54 | 14 | 35 | 37 | 2,5 | 15 | 50 |

| 14 | 20 | 54 | 14 | 35 | 37 | 2,5 | 15 | 50 |

| 16 | 30 | 83 | 20 | 54 | 55 | 4 | 30 | 110 |

| 20 | 30 | 83 | 20 | 54 | 55 | 4 | 30 | 110 |

Specification

Stainless steel precision castingA4

- Weldable

- AISI 316

Plunger pin

Stainless steel AISI 316

Pressure spring

Stainless steel AISI 316Ti

RoHS

Information

With stainless steel spring latches GN 722.1, the plunger pin is retracted over the curve of the guide by a 180° turn of the latch. The notch at the upper end of the curve causes the latch to be held in place if the plunger pin needs to be kept temporarily from protruding. The stainless steel A4 version is suitable for use in particularly aggressive environments.

The dimensional tolerances between plunger pin and guide are selected so that the functional reliability is guaranteed even after welding, applying a corrosion protection layer or in case of contamination.

For fastening by welding, the unmounted type AU is particularly recommended to avoid changes to the microstructure of the material due to heating of the spring and plunger pin. In this case, the indexing plunger is assembled only after the surface treatment of the welded guide.

see also...

| How to order |

| ||||||||

GN 722.1-8-20--AU-A4 |

This could also be interesting...

-

-

-

-